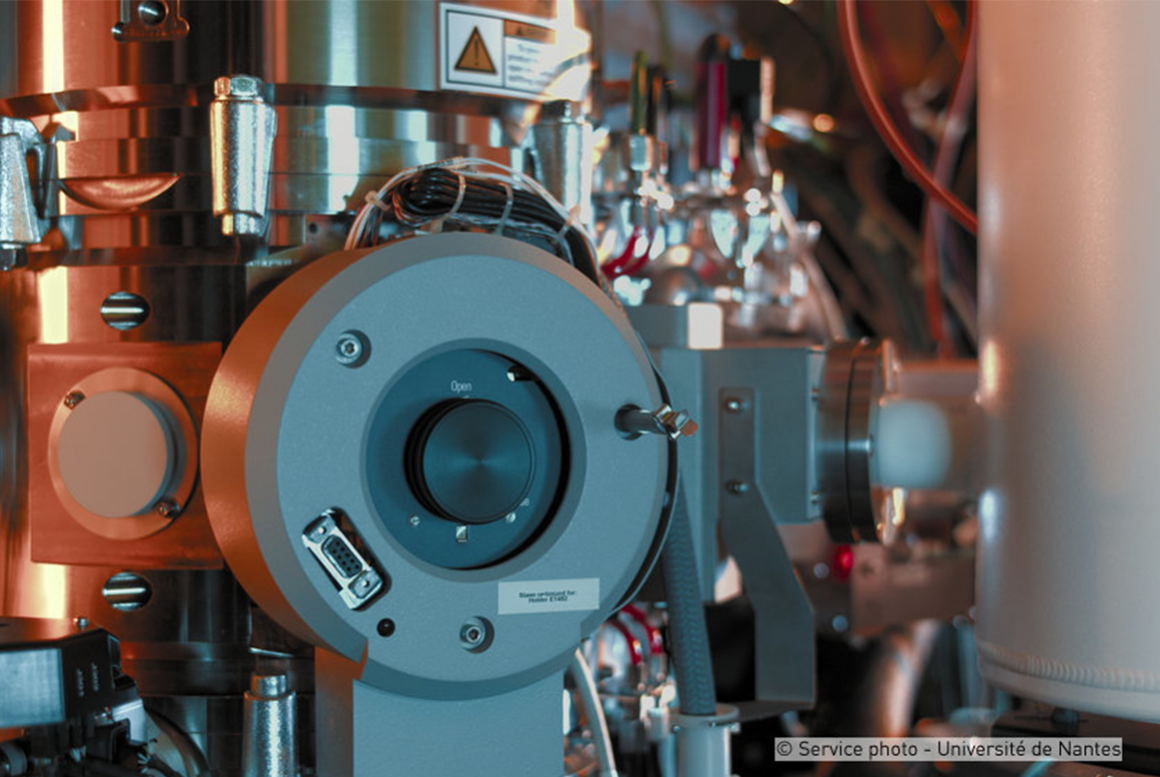

University of Nantes: an electron microscope on the cutting edge of European research

The exceptional configuration of this microscope called “Nant’themis” (monochromator, probe corrector, energy filter with direct detection camera) is the first to be installed in Europe.

Developed by the Jean Rouxel Materials Institute (IMN-CNRS/University of Nantes), it is made available to IMN researchers as well as local, regional and national laboratories, working in various fields including metallurgy, energy and biology. Industrial companies also have the opportunity to use the powerful electron microscope with the help of IMN researchers.

Extra-powerful: the microscope “could tell us what a tennis ball on the Moon is made of… from Earth!”

World first: 3D printing of a hollow stainless steel propeller blade

This project headed by Naval Group and the École Centrale engineering school in Nantes represents 48 months of R&D involving 37 partners from 12 countries. The project leaders call it a real “technical prowess”, in that the 3D printing process will achieve weight gains of over 40% compared to a conventional process.

For more information: Naval Group

Production of complex composite parts: 2 new high-tech systems for the IRT Jules Verne

- The Tobeca 3D printer for high performance composites will be used to evaluate the performance of Fused Filament Fabrication (FFF) extrusion technology.

- The EOS P810 laser sintering machine will make it possible to evaluate the performance of this process applied to these demanding materials and to test new powders to reach the standards required by the aerospace industry. This machine is the only representative of this technology capable of processing high temperature materials such as PEKK or carbon-loaded PEKK and is currently the only one available in France.

For more information: IRT Jules Verne

日本語

日本語  Français

Français